실재가격이아닙니다 Tablet 의 물리적 성질을 측정하는 장비로서 무게,경도,두께,길이를 자동으로 측정 하는 장비 입니다.

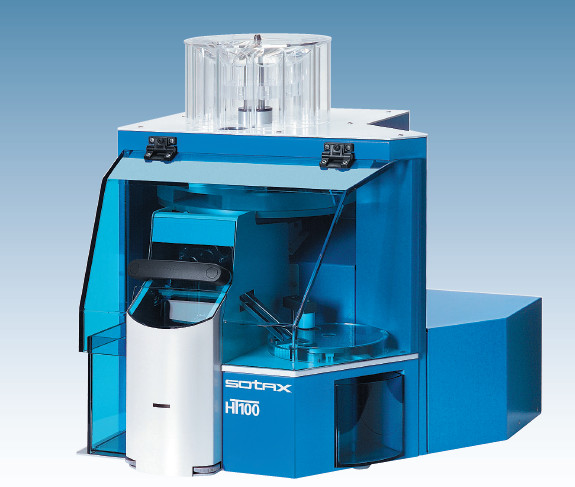

Tablet Testing System

Tablet 의 물리적 성질을 측정하는 장비로서 무게,경도,두께,길이를 자동으로 측정 하는 장비 입니다.

The fastest automated tablet testing system with the revolutionary Auto Alignment™

and Auto Separator device ensures consistent, trouble-free results for all shapes and

sizes of tablets batch after batch.

Automated testing of the most important physical parameters (weight, thickness, diameter or length and

hardness) of up to 10 different products or batches, e.g. tablets, dragées, oblongs, effervescent tablets or similar

drug delivery systems

Separates all shapes and sizes of tablets with ease, using the vibration-free Auto Separator, no manual

adjustments required

Equipped with the Auto Alignment™ device (patented) which automatically aligns even the most difficult of

tablet shapes, to prevent erroneous hardness measurements

Two hardness measurement principles “Constant Speed” and “Constant Force”, measuring range as standard 4

to 500 or 1000 N

Controlled by our 21 CFR Part 11 compliant and LIMS capable Q-Doc software for Windows 2000/XP/Vista

Meets the USP chapter 1217 requirements: three points calibration and tablet orientation

Ten-chamber feeder

The optional batch feeder has ten chambers. Each chamber can hold 200

samples or more (dependent upon size and shape). Chambers may be filled

with different batches of tablets or combined as one large single batch.

The feeder cover serves two purposes, namely to load samples into the

chamber and to protect the tablets against dust. The magazine is easily

removable and easy to clean.

The feeder moves clockwise and transports the samples into the Auto

Separator.

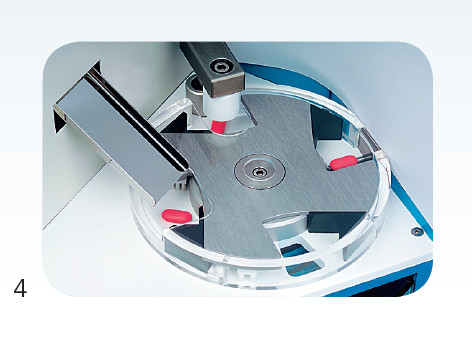

Auto Separator

With the Auto Separator it is possible to separate all shapes and sizes of

tablets without any manual user adjustments or special tools.

The separation is achieved through a new device based on soft rotation

(instead of vibration).

The Auto Separator is removable and can be easily cleaned.

A photoelectric sensor is positioned on the outside of the separator to

detect each individual sample as it is deposited from the separator to the

balance boat.

Balance boat

The weight of each sample is determined using a balance boat and this is

designed to eliminate errors caused by a build-up of tablet debris and dust.

The tablet weight is measured with a high-speed, precise Mettler weight

cell.

The weight cell is positioned separately from the SOTAX HT 100 housing.

The two balancer screws on the Mettler weight cell are easily accessible for

leveling the balance boat.

The balance boat is equipped with two slides, enabling to check only the

weight of gelatin capsules or other samples before being collected in a

special container.

The balance boat can be removed easily for cleaning.

The tablet is moved smoothly from the balance boat into the transporter.

Transporter

The four-station transporter feeds the tablet clockwise from each test

station.

The Auto Alignment™ device (patented) on the hardness testing station

guarantees that all common forms are positioned correctly.

The feed path and the test jaw are automatically cleaned of tablet

debris by special brushes mounted on the transport head. Broken tablets

are automatically swept away into a waste container

Thickness measuring system

Thickness is measured by calibrated precision potentiometric displacement

sensors.

The measuring plate is ball bearing supported for easy adjustment and to

ensure that this plate remains parallel to the test platform.

The thickness measuring system is automatically zeroed after each test run.

Hardness measuring station

Equipped with the Auto Alignment™ device (patented), to position

automatically and rapidly all common forms at exactly 90 degrees to the test

jaw before testing.

An automated cleaning device that protects the hardness station from tablet

residues is included.

The measuring plate is ball bearing supported for an easy adjustment and to

ensure that it remains parallel to the test platform.

Measurement by “Constant Speed” or by “Constant Force” is selectable.

The jaw speed movement and the linear increase of force are adjustable.

These techniques compare and reproduce results of all common hardness

testers.

무단수집및 복재를 금합니다 .

상품정보고시

| 제품명 |

HT100 자동화 경도 시험기,알약자동경도기, Automated Hardness Testing |

| 판매가격 |

가격문의 |

| 브랜드 |

SOTAX |

| 원산지 |

Swiss |

| 제조사 |

SOTAX |